| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

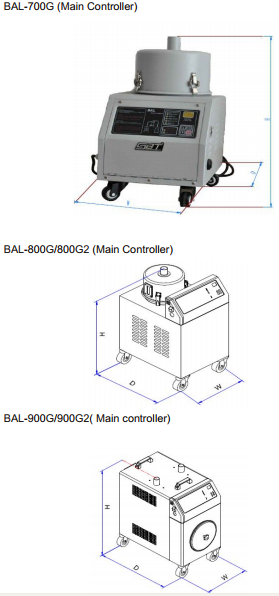

Separate Vacuum hopper loaders are suitable for conveying material over long distance. The material hopper is installed away from main unit and use of a stainless steal hopper eliminates material contamination. Superior suction power is continously available from the high efficient vacuum blower. Each model is equipped with motor overload protector to prolong it life, and is also fitted with a material shortage alarm.

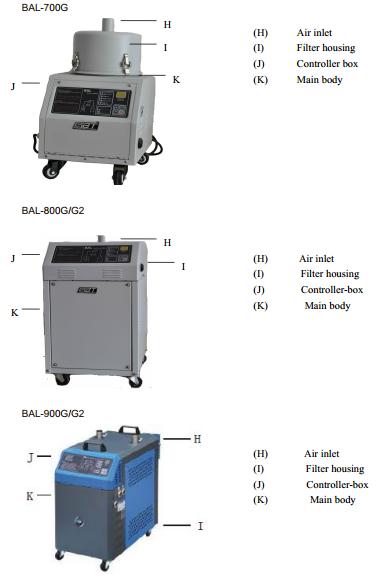

1) Separated design of main unit and hopper receiver allows a great level of convenience when in use.

2) Stainless hopper receiver to eliminate the contamination.

3) Microprocessor controlled for ease of use.

4) Digital display clearly shows operating status.

5) Motor overload protector ensures long motor life.

6) Audible material shortage alarm.

7) Filter designed for easy cleaning.

8) Observation window to check air filer status.

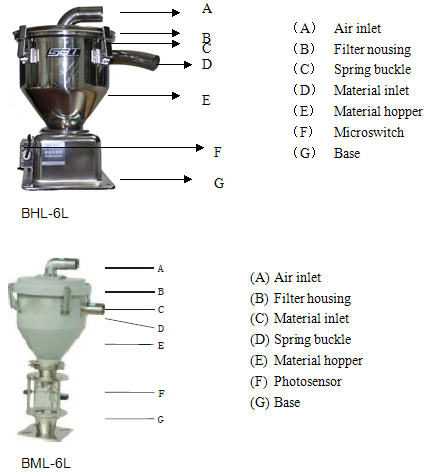

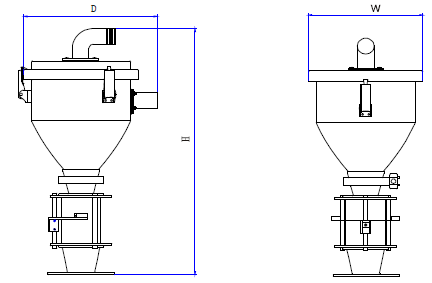

9) Vacuum hopper receiver (BHL type) can be mounted directly to machine hopper; Glass-tube hopper receiver(BML) can be mounted directly to machine throat.

Note:

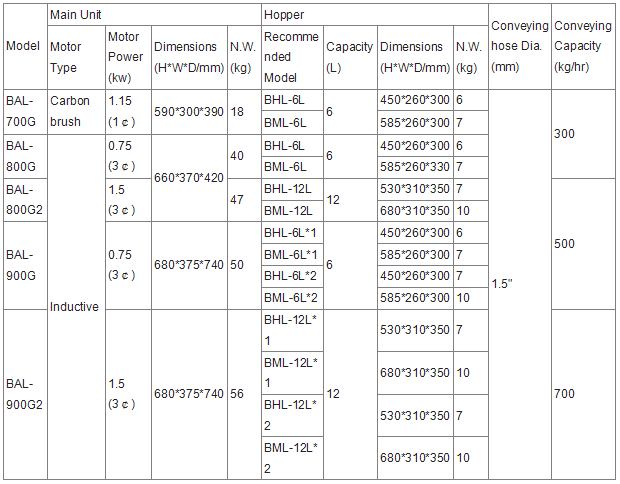

1) "2" stands for 2HP blower.

2) "G" stands for separate design of hopper receiver(s) and main unit.

3) "BHL" stands for vaccum hopper receiver, "BML" stands for glass-tube hopper receiver.

4)For hopper inside polished ones,plus “P”at model behind.

5)It is available to select ACF -1 cyclone dust separator (additionally mount at/back of main unit)

6)Test condition of conveying capacity :Plastic material of bulk density 0.65,dia ,3-5mm,vertical conveying height:4m,horizontal conveying distance:5m.

7) Power supply: 3 phase, 400V,50Hz for all models except BAL-700G ( single phase, 230V, 50Hz)

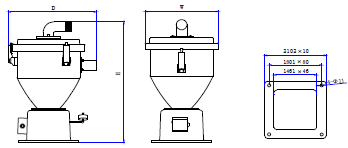

BHL-6L/12L

BML-3L/6L/12L

BAL-G series "Econo" Separate vacuum hopper Loaders are suitable for conveying plastic granules over long distance. Utilizing high efficiency vacuum blower to produce vacuum in material hopper, plastic materials will then be fed into material hopper by outside pressure.

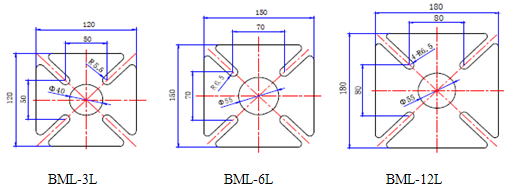

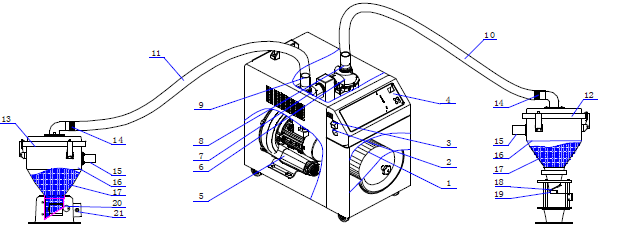

1. Blower 2.Spring clip 3. Filter 4. Filter house

5.Suction tube 6.Switch 7.Buzzer 8.Hopper suction tube

9.Material inlet pipe 10.Hopper 11.Material 12.Material defleltor plate

13.Micro-l switch 14.Base

After start, blower (1) began to work, vacuum inside of material hopper (10), meanwhile non return flap (12) is closed. Materials will be drawn into material hopper (10) by pressure difference through material inlet (9). When material suction is completed, materials automatically fall down by self gravity. Motor will start to work again when reed switch (13) detects no materials left in the hopper.If the machine cannot draw materials for three times, the red alarm lamp (7) on control box will blink.

1. Filter 2. Buzzer 3.Switch 4.Operation panel 5. Blower 6. Diaphragm valve 1 7. Diaphragm valve 2 8.Air suction hols 1 9. Air suction hols 2 10. Suction tube1 11. Suction tube2 12. Hopper 1 13.Hopper 2 14.Hopper suction tube 15. Material inlet pipe 16.torage bin 17. Material 18.Reverse stopping flap 19. Opposite-tgpe photoelectrial sensor 20. Material defleltor plate 21.Micro-l switch

After turn on the altemative swich,via the operation panel (4)to set suction time of the loader 1(12)and loader2(13),Then press the start button,blower(1)starts work,diaphragm valve1(6)opens and diaphragm valve2(7)closes.flap plate(18)close,then hopper start to dwaw material After materal suction finishes,blower stops.Because the deadweight ,material drops down.After the microswitch(21)find loader2(13)hs no material,blower(1)starts again.And solenoid valve makes the diaphragm valve1(6)close,diaphragm valve2(7)open,and flap plate(20)close,loader2(13)begins to draw material,after finished,if photoelectric switch(19)find loader1(12)has no material,via the solenoid valve to make moteor start and draw material again.The machine work according to this cycling,If can’t suction the material or no material ,the buzzer on the control panel will be alaming.

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.